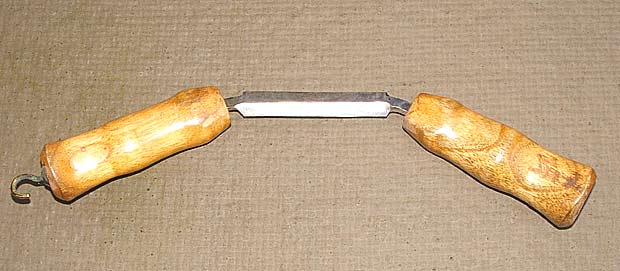

Here is an old favorite with madrone handles. A 7" Greenlee. I love a straight blade knife best. Homemade Greenwood Handles Rehandling the drawknife is an exercise you might as well get into. You can get a good blade with bad handles for about a nickel ninety eight anywhere. New drawknives are expensive. With as many good old blades as there are around, I'd be embarrassed to pay much for one. There are more than enough other temptations to spend your money on. Get you some green wood and just boil it! Madrone is a notorious cracker of a wood. It wants to crack when drying very easy. It's near as bad as manzanita for the local woods. I had an oldtimer tell me one day many years ago, take a saw out into the woods and cut green wood straight from the tree. Drop it in a pot of boiling or at least simmering water and leave it there for one hour per inch of thickness. Take it out and next day you can begin to work it and it'll never crack (unless you end up leaving it out in the rain like a dope). Naturally this only works for pieces small enough to drop into a pot. Unless you build a boiling tank. A friend and I did this once out of an old hot water heater tank. Anyway, however you do it, it works. I've never lost a piece to cracking that I boiled. It has to be green, fresh cut though. Don't be expecting to get away using semi dry wood. Next day you can put them on the lathe and turn them to shape, which is exactly what I did. Come to think of it, I'm not even sure I waited that long.

I "burn in the tangs". This means drilling a small pilot hole all the way through the new handles you just turned (best done on the lathe since the bit wants to follow the centerline so much better than any other way). Then the blade is secured in a big heatsink just at the bottom of the tang, a vise works best. The tang is next brought up to red heat with a propane torch (or a pair of them works even faster). The handle will literally fall on most of the way, smoke billowing. So quick, jerk it back off, run and open the window. Now heat it up again and this time push it on until it's about 1/8" from where you want it to permanently stay and pull it off one last time. When it cools, knock it on for keeps. It will last forever or until you do something wildly dumb.

If you lose or damage your washers, just make some new ones. Only takes a few minutes. Cut some out with a holesaw. To get the dish shape to em, lay over top of a ring of steel pipe or a large mechanics socket and hammer the dish with the ball end of a ball pein hammer.

|