Fix That Tote

Fix That Tote

August and Most Serious Galoots

The following is a most sincere invitation to a better life for you.

So, tell me, Galoots young and old....

How many times have you passed on a good plane just because the tote was

chipped?

Tired of all those chipped totes you already have in your life are you?

Suffering from sleepless nights while your skin is flaking like snow and

your nerves are shot to smithereens from one more great tool you had to walk

past because the tote was chipped?

You think you can't fix it? Think it's too hard and you'll never get a

good job and it'll stick out like a sore thumb from 55 yards away? Well

fret no more!

Have we got the cure for you! A secret good men have died to protect.

The very miracle of the age. Passed down hand to mouth by the secret fakirs

of ancient legend, simple and perfect everytime.

And.......... If you act now we'll throw in, completely free and

without further obligation, for only the price of postage or a good mellow

drink, whichever is cheaper.................

Now, who will be the first? Step right up, don't be shy

|

|

| |

|

|

Only

one in 3planes out there in the wild escape the chipped tote horn. At the

swap meet or yard sale or ebay it makes most of the difference between a $5

plane and a $50 plane.

You know the story.

You see a great plane and there you are wondering if you should take it or let

it go. Most will just leave it be because finding a good original tote can cost

about as much as another whole plane with a perfect tote and it takes time to

find even a single one. Replacement newly made totes are available but again

these cost about as much as the plane you were thinking of putting them on many

times. And about 75% of the time it's the tote tip that is chipped or missing in

action. We've all seen it and passed them by about a million times mostly just

for this defect alone.

But fixing them is easy! Easy I say.

The trick is cutting off the offending area

parallel with the bottom. If the cleanup cut is made any old place you can't get

a clamp on it. Without a clamp your repair is going to stick out like a sore

thumb from 50 yards and probably fall back off in a year or two. When it's

parallel any vise or sturdy clamp will give you plenty of pressure to make a

tight permanent glue joint. It's why clamps were invented.

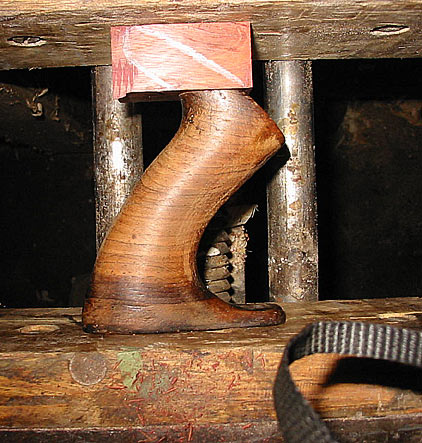

There are other ways of squaring up your

gluing surface, I know, but the easiest and fastest for me is shown here.

|

| |

This is an ordinary table saw rip fence with

the tote being cut.

A

good sharp fine tooth blade and a slow easy feed does it here.

This results in a smooth flat surface parallel to the base.

Next, pick through your scraps for a nice grain match in rosewood. If you have a

different species of rosewood that's ok, you can stain to match easy later, just

try to line up the grain lines.

This is a

scrap of purpleheart I just grabbed and placed on top.

|

You'll want to be sure to select your repair

piece oversized. Longer, wider and thicker if you can. Make the horn longer and

especially watch the curve up the back. It'll look larger than it really is at

first. Once you start to round this off it begins to look differently, so leave

extra. I realize this picture makes it look like I marked out for minimal but

trust me it's considerable bigger than it looks. See what I mean about not

trusting your eyes?

Of course you will be grain matching

rosewood instead of purpleheart. I just wanted it so show up for the picture.

I've read many accounts of gluing rosewood.

I've tried lots of different types of glue

too. One school says you need to remove the natural oil present and I've used

acetone for that. I've even taken the point of a scratch awl and scratched up

the gluing surfaces taking care not to go beyond the finish lines. I did this

for years and used epoxy or polyurethane glue. Gradually I started to use less

and less of this extreme precaution though. These days I simply use ordinary

yellow carpenters wood glue available anywhere. After 24 hours in the vise I

cannot break the bond with my hands alone, even pressing between my knees, so I

figure that's good enough for the girls I know. I've never had one fail on me.

It's the smooth gluing surface and even clamping pressure that seems to do it.

Once it's cured well

Take it out of the vise and give it a good

tug. Really try to break it. You'll see, you can't.

OK, weightlifters and guys who can pull 26

loaded semi trucks down the road with a rope in their teeth might be excused

from this part. But a good strong average pull is my point. It'll hold.

Carve it to shape.

I will use round rasps and files. I

especially like the small 6" shoe rasp with fine rasp teeth and coarse file

teeth, both flat and 1/2 round. When these are sharp they are just a joy.

Next comes a scraper. I like them thin,

narrow and flexible for curved work like this. There is another article on

making the flexy scrapers on this site.

Finishing

After scraping it's possible you'll need to

sand it some. I'll use strips of belt sander belt, ripped into narrow strips and

applied shoeshine style. My final sanding never goes past 220.

After sanding I polish rosewood and anything

harder than that. A med sewed cotton buffing wheel, turning around 1000 rpm and

med aluminum oxide polish will make it sparkle in minutes. Once you've buffed

rosewood you'll never go back to any other kind of finish. It looks great, feels

like warm buttah against your skin and if you need to renew it for some reason

it only takes 5 minutes more.

Staining

In case your rosewood patch didn't quite

match for color, I've found an interesting thing. Minwax Jocabean stain, a

deep muddy brownish black color, usually always brings the tone right close to

Indian rosewood. Even on the lighter rosewoods like Bolivian the color match is

spot on. It's the grain pattern you need to watch when aligning the patch. After

that the color is easy.

Both these totes were repaired using this

method.

yours Scott

Fix That Tote

Fix That Tote